|

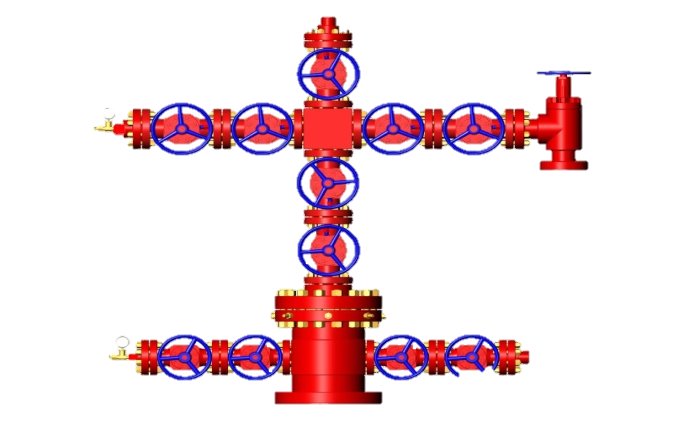

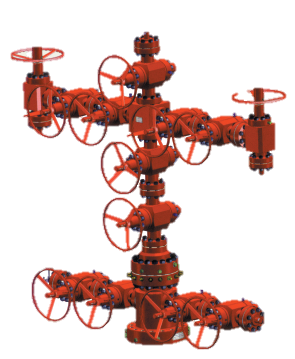

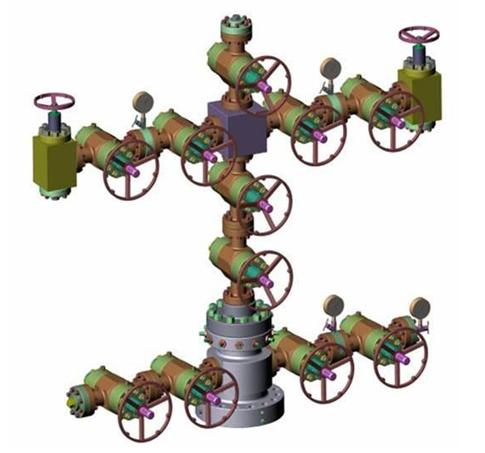

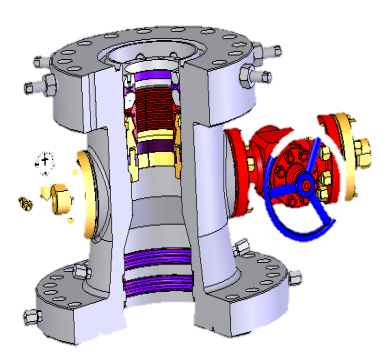

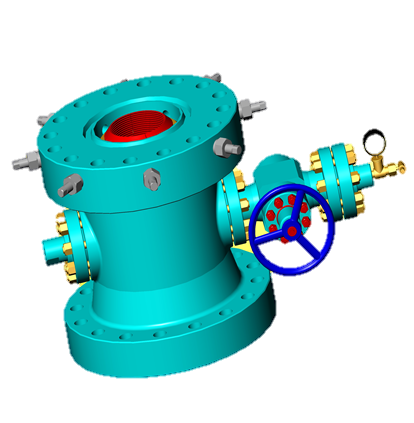

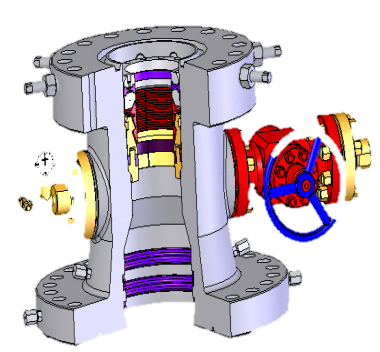

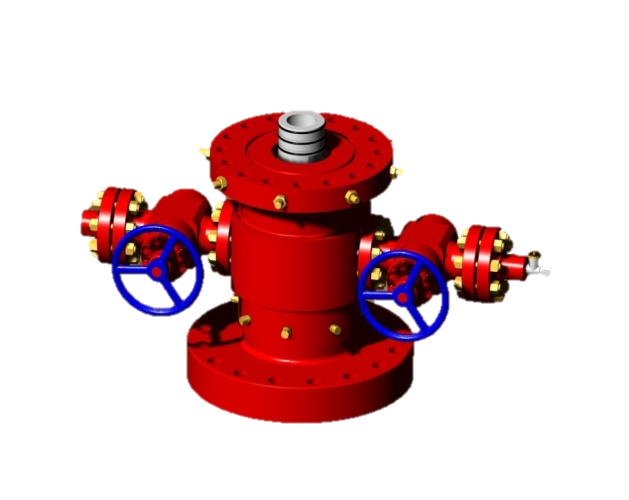

X-mas Tree & Spare partsMain technical parameters

Sizes: 1-13/16″~ 9″ Pressure: 2M, 3M, 5M, 10M, 15M, 20M Working medium: petroleum, natural gas, mud, gas Containing H2S and CO2 Working temperature: K~X (-75 oF ~ 350 oF) Material class: AA, BB, CC, DD, EE, FF, HH Product specification level: PSL1,PSL2,PSL3,PSL4 Performance requirement: PR 1~2 |

The Christmas tree manufactured by our company is used for controlling the wellhead pressure and adjusting the output of the oil & gas well and also can be used for special operations such as acidification, fracturing, water injection, and high temperature steam injection and testing, etc. The Christmas tree can meet different working conditions. It has reliable sealing and safety operation. The design, manufacture, experiment and quality control are all in accordance with the requirement of API 6A 20th edition.

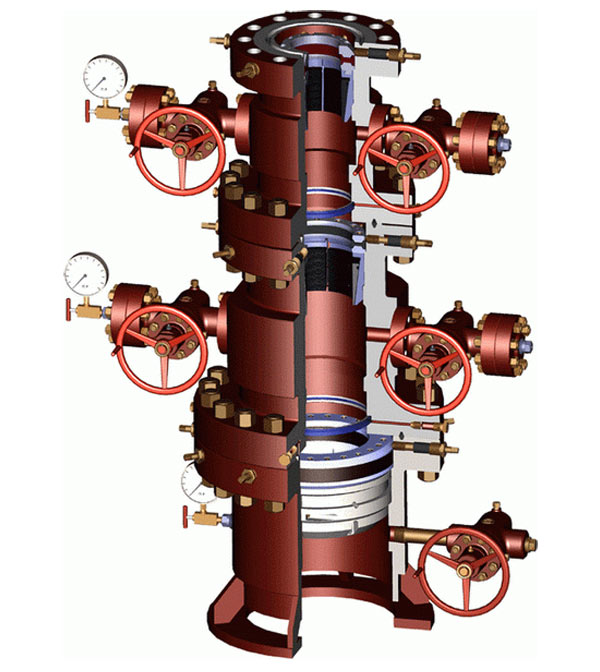

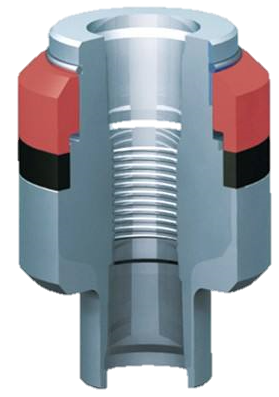

Casing Head

Casing head prevents damage to sealing areas from drilling tools and prevents test-plug and bowl-protector wedging problems under pressure. This straight bore design also reduces maintenance costs and permits suspension of heavy casing loads.

Casing Head Spool

v The sub - seal of casing head spool is BT - type structure, and the sealing is safe and reliable

v Users can choose slip type or spindle type hanger according to their needs

v Can be suspended in all sizes of casing

Tubing Spool

v Made of API 6A low alloy steel or stainless steel

v Nominal size of top flange (in): 11, 7-1/16 top flange

v Nominal dimensions of bottom flange (in): 7-1/16, 11, 13-5/8

v Bottom flange working pressure (psi):2M, 3M, 5M, 10M, 15M, 20M

v Side outlet nominal size (in): 2-1/16, 2-9/16

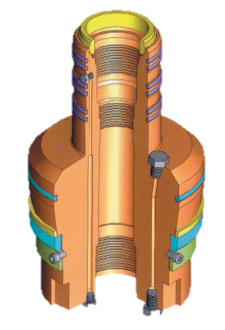

Tubing Hanger

Tubing hanger can be customized or individually designed to meet customer requirements in all aspects, including size, rated pressure, thread and BPV type, type of seal and port of electric submersible pump (ESP), control line, chemical line, etc.

The hanger is designed for up to 20,000 PSI working pressure.

v With chemical injection Channel

v BPV Thread

v With capillary pores throughout the channel

v With cable through hole belt positioning mechanism

v Control pipeline access with subsurface safety valve

Sweep the QR code to learn more!

UAE Office

Sweep the QR code to learn more!

UAE OfficeEmail: gary@ekfworld.com

Tel: +971 50 8152530

Address: PO Box 261529, Jebel Ali, Dubai, UAE China: 1. Dongying Tianjin Petroleum Technology Development Co.,Ltd

2. Shandong Hongji Petroleum Machinery Equipment Co., Ltd

Email:edwin@ekfworld.com

Tel: +86 13854652530

Address:Dongying, Shandong, China 25700 US Office

Email: yuhai@ekfworld.com

Tel: +1 832-866-4698

Address: 10641 Harwin Dr, Suite 510, Houston TX 77036