|

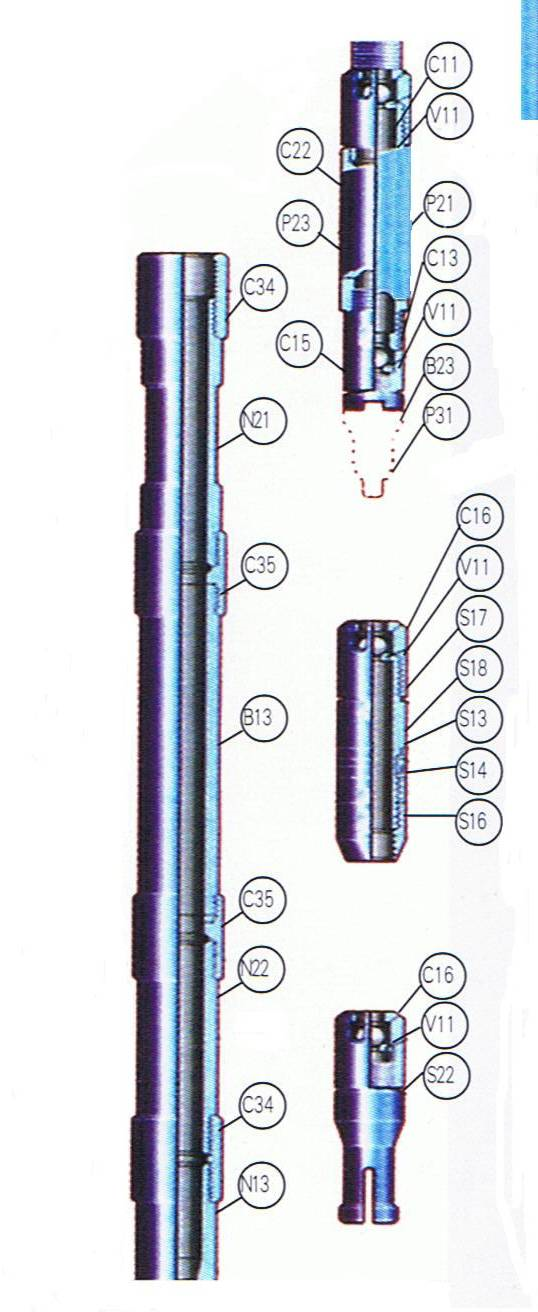

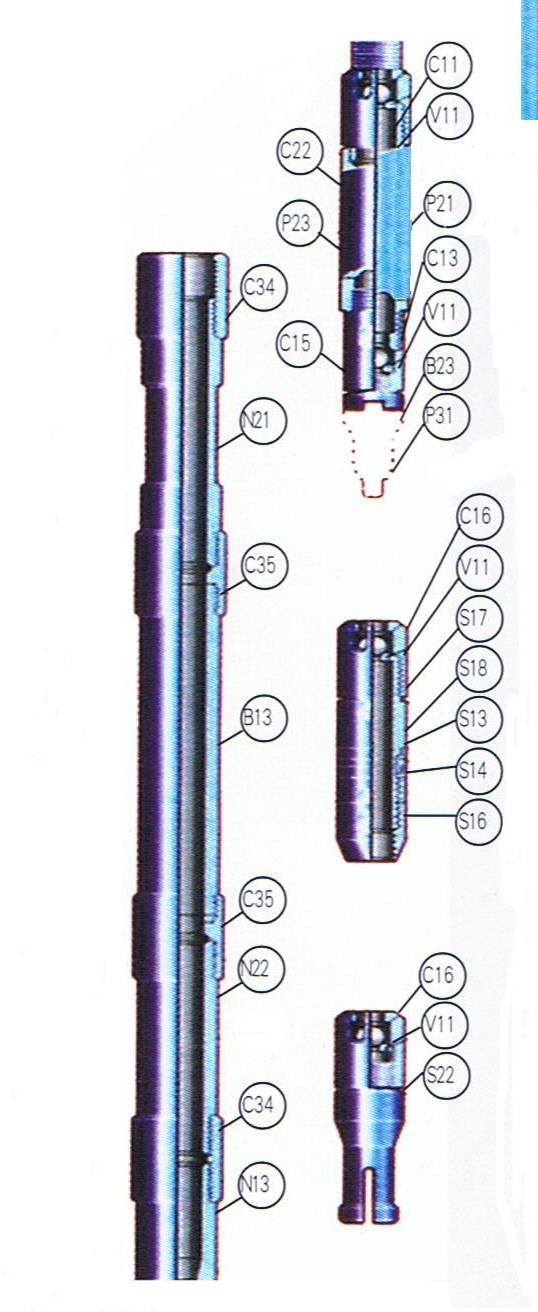

SUCKER ROD PUMP & SPARE PARTS (API 11AX) |

The whole pump can be assembled and connected to

the lower end of the sucker rod on the ground, run into the well as a unit and

fixed in the tubing by seating nipple pre-fitted in the tubing at the required

depth (pump setting depth). The workover operation time for a rod pump well is

much shorter than a tubing pump well by at least 50%. Rod pump have three

types. They are Traveling Barrel Bottom Anchor Rod Pump, Stationary Heavy Wall

Barrel Bottom Anchor Rod Pump and Stationary Heavy Wall Barrel Top Rod Pump.

Features and

specification:

1) Nominal bore size: 32 - 57mm(1.25~2.25 in)

2) Plunger length: 1200 - 1800mm (4~6 ft)

3) Tubing size: 2 3/8 - 3 1/2

4) Length of stroke: <7.5 m

Typical Model: 20-125RHAC;25-175RHAC;20-125RHBC;25-175RHBC;30-225RHBC Etc.

Tubing Type Sucker rod pump

The barrel assembly and the standing valve assembly of the pump can be mounted and connected to the tubing on the ground, which are run into the well first, then connect the plunger assembly with the lower end of the sucker-rod and run into the pump. Tubing pump has the characteristics as large flow rate, tight and sound structure. Standing valve has two types: non-pullable and pullable. The pullable standing valve tubing pump has cup type and mechanical type.

Feature and specification:

Conforming with API Spec 11B

1) Nominal bore size: 32 - 120mm(1.25~4.75 in)

2) Plunger length: 900 - 1800mm (3~6 ft)

3) Tubing size: 2 3/8 - 4 1/2

4) Length of stroke: 600 - 7300 mm

Typical Model:20-125TH;25-125TH;25-150TH;25-175TH;25-225TH;30-275TH;40-375TH

We also supply the API spec 11AX Down hole pump spare parts, such as the Pump Barrel, Plunger, Valve Ball and Seat, Seating Nipple and etc as per the customer requirements.

Sweep the QR code to learn more!

UAE Office

Sweep the QR code to learn more!

UAE OfficeEmail: gary@ekfworld.com

Tel: +971 50 8152530

Address: PO Box 261529, Jebel Ali, Dubai, UAE China: 1. Dongying Tianjin Petroleum Technology Development Co.,Ltd

2. Shandong Hongji Petroleum Machinery Equipment Co., Ltd

Email:edwin@ekfworld.com

Tel: +86 13854652530

Address:Dongying, Shandong, China 25700 US Office

Email: yuhai@ekfworld.com

Tel: +1 832-866-4698

Address: 10641 Harwin Dr, Suite 510, Houston TX 77036